Product Details

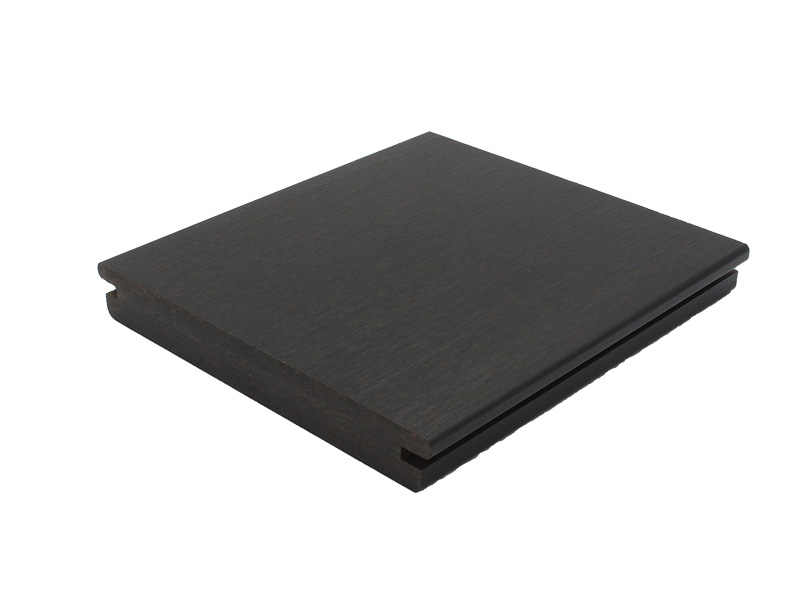

Garden Fence Outdoor Bamboo Decking Board T&G Bamboo Flooring

Strand woven bamboo decking boards are made from compressed, the fine bamboo fibers under intense pressure, while using a heat-sensitive and low-VOC adhesive. THJ outdoor Bamboo materials has a series of excellent features, including the high stabillity and high anticorrosive, high density high abrasion, high hardness and anti-termite etc. Bamboo decking board is suitale for outdoor applications. With THJ outdoor bamboo decking for building, decoration, landscape, articles of daily use and art-wares, etc. These materials can be customized individually to meet your own requirements.

THJ outdoor anti-corrosive bamboo developed by our unique patented technology, is a high-tech new eco-friendly material, which is widely used as beautiful and durable flooring and wall panel, it remains the high intensity of the bamboo and its performance can be compared with those woods with over 100 years and the fire rating can reach up to B1.

Test item | Result | Standard |

| Fire resistance class | B-s1, d0 | EN 13501-1 :2018 |

Hardness | 70.4Gpa | |

| UV exposure | Grade 4 | ISO 4892-3:2016 |

| Density | 1.15-1.18kgs/m3 | |

Moisture rate | 8-12% | |

| Expansion rate or water absorption | 0.35% | |

| Formaldehyde release | 0.001mg/M3 | |

| Swelling in thickness after immersion in water | 0.20% | EN317:1993 |

| Determination of resistance | 8.61N/mm2 | EN1534-2010 |

| Flexural test | 12900Mpa | EN ISO 178:2010/Amd.1 :2013 Method A |

Specific Gravity | 1.14 | ASTM D2395-07 Method A |

| Light Ageing Test-UV Exposure | Grey scale 3-4 | ISO 4892-3:2016 Cycle 1 & ISO 105-A02:1993/Cor.2 :2005 |

| Slip resistance | SRV “dry” =74 | CEN/TS 15676:2007 |

| Durability test | refer to file | CEN/TS 15083-1 :2005; durability Classification according to EN 350:2016 |

| Resistance to indentation | 150MPa | Test method: EN 1534: 2020 |

Lifetime | 25 years |

Installation manual

1.Decking with symmetrical grooved in two length sides can be fixed with clipDC 05-1. Distance between the decking is about 6-7mm after installation. 2.Decking with H&L grooved in two length sides can be fixed with clip DC 05-2.Distance between the deck is about 5mm after installation. 3. Decking with symmetrical or H&L grooved in two length sides can be fixed with clip DC 07. Distance between the deck is about 4mm after installation.

Consideration: 1.before installing, please keep the products in dry and shade place, avoid the sunshine and the rain. Defects in surface caused by improper storage, is insufficient to cause customer complaint. 2.Before installation, clean up the worksite, make sure the basic is flat and stable, the drainage is smooth and comforms with the requirement of the construction design. 3.The joists should be fixed on stable cement-blocks or cement-tiles.Ensure decking slope 1-2 degrees from level inorder to shed water. 4.The distance between the joist must be between 450-500mm. By a deck of 1860 length need min.5 joists. 5.Distance from floor to the bottom of the decking should be 80-150mm.

Maintenance manual:

1. Clean up the ground trash soil (such as water washing need to wait for the floor to dry after the next step), and prepare the floor wire brush, sanding machine, floor protection oil, floor shine oil and other tools.

2. Clean the ground, prepare wire brush, sander, polishing machine, protecting oil, etc.(if clean with water, please make sure the ground is dry before the next step)

3. The floor is sanded with a wire brush to clean the surface layer of softened and decomposed varnish.

4. Please sand the decking with wire brush and clear the paint film on the surface.

5. Rinse off the paint film and dirt that comes off the surface of the panel after sanding with water.

6. Please clean the surface of the decking with water.

Prev :Hot Compressed Outdoor Strand Woven Bamboo Decking Boards for Plank Road

Next :Construction Grade Natural Floors Antique Bamboo Outdoor Deck Flooring