Product Details

Anti-corrosive Outdoor Bamboo Decking Floor , Exterior Bamboo Panels

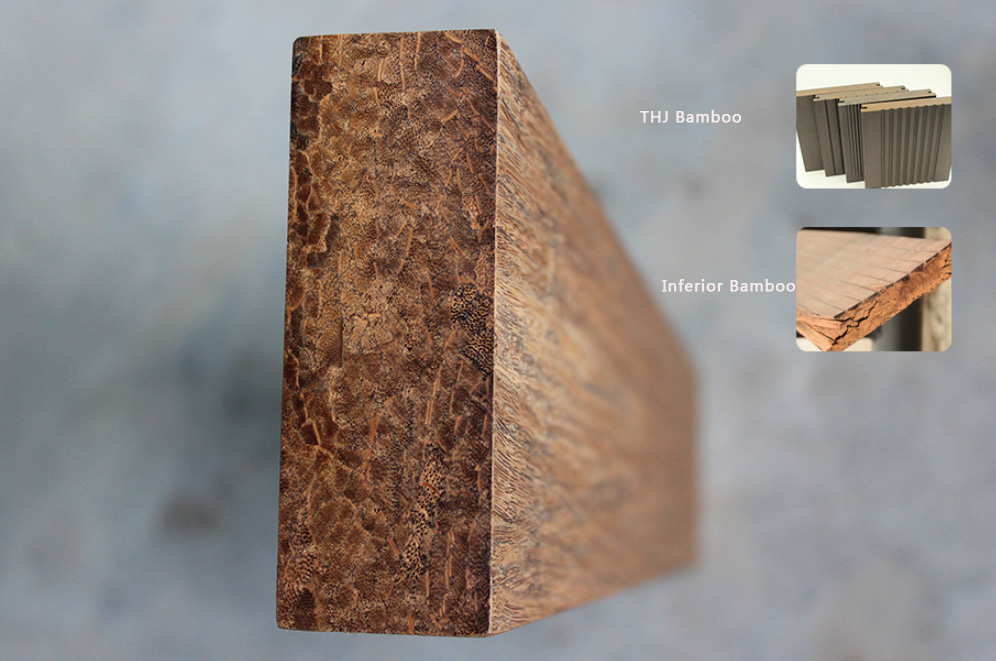

THJ outdoor anti-corrosive bamboo developed by our unique patented technology, is a high-tech new eco-friendly material, which is widely used as beautiful and durable flooring and wall panel, it remains the high intensity of the bamboo and its performance can be compared with those woods with over 100 years and the fire rating can reach up to B1.

Bamboo decking boards are made from compressed, heat-treated bamboo fibers. THJ outdoor bamboo materials has many outstanding features: good eco-friendly, high stabillity and high anti-corrosive, high density high abrasion, high hardness and anti-termite etc. Bamboo decking board is suitale for outdoor applications. With THJ outdoor bamboo decking for building, decoration, landscape, articles of daily use and art-wares, etc. These materials can be customized individually to meet your own requirements.

Product details:

Item | Outdoor Bamboo Decking | Technics | Hot pressing |

Material | Bamboo+Dynea Glue | Color | Coffee color or caramel color |

Texture | Flat/Big wave/Small ripple/Small groove | Hardness | 106.8N/mm² |

Density | 1200kgs/m3 | Moisture rate | 7-13% |

Common Size | 1860*139*18/20/30/38mm | Expansion Rate After 1 Hour In Boiling Water | 4-5% |

| Joint | Tongue& Groove | Surface treatment | bleached, sanded, with UV coating or outdoor oil |

Certification | ISO/SGS/EPH/TUV | Package | Export carton with PVC on pallet |

Feature | Anti-corrosive, Eco-friendly, termites resistance/ fireproof/ anti-friction/ high hardness/ high stability/ high bending strength/high density | ||

Application | Garden, Park, Fencing, Swimming pool, railing, Balcony, Patio, Terrace, Square, Commercial buildings and any outdoor environment | ||

OEM and customization acceptable

Compared with other wood:

1. Natural anti-corrosion solid wood (Merbau,Teak, etc )-- Natural and beautiful, but not anti-termite, bad for forests resources,violating the ideas of environmental protection.

2. Chemical anti-corrosion wood ( CCA )-- Containing heavy metals and toxic chemical composition ( Arsenic),polluting environment, prohibited in United States, Japan and EU countries.

3. Chemical anti-corrosion woods ( ACQ ) --Non-toxic processing under chemical methods, bad mucor proof, limited application ( unfavorable to touch soil ).

4. Carbonized wood-- Good Eco-friendly performance, wide usage, but damage to forest resources and limited application ( unfavorable to touch soil ).

5. WPC --A kind of completely industrial products, not natural, easy to be deformed, fragile and broken, hard to be dissolved and not Eco-friendly.

Date comparison

Tab.1

Performance | THJ Outdoor bamboo | Nature anticorrosive wood | Man-made anticorrosive wood | Carbonized wood | WPC |

Principal | Through physical process, hot pressing, carbonized | Nature corrosion | Preservative treatment with chemicals | Carbonized in high temperature | Plastic processing technology |

surface | Unique grains of bamboo (brown and dark color) | Keep the original wood grain | Green in color | Dark color-brown | Dull |

Abrasion-resistance corrosion | Excellent | Good | Good | Good | Good |

Environmental preformance | Excellent | Excellent | Bad | Good | Good |

Anti termite | Excellent | Bad | Good | Good | Good |

Stability | Excellent | Good | Easy shaped | Good | Easy shaped in high temperature |

Market price | Middle high | Highest | Low | Middle | Middle Low |

Tab.2

No. | Species | Moisture rate(%) | Density (kg/m3) | Expansion rate of water absorption % | Hardness(Gpa) |

1 | THJ outdoor bamboo | 4.7 | 1.23 | 0.35 | 70.4 |

2 | Teak | 9 | 0.7 | 0.4 | 55.8 |

3 | Merbau | 14 | 0.8 | 0.41 | 61.7 |

4 | Red cedar | 12 | 0.35 | 0.6 | 44.1 |

5 | Jarrah | 17 | 0.57 | 0.6 | 47.1 |

6 | Carbonized pinus sylvestris | 12 | 0.43 | 1 | 44.3 |

7 | Pinus sylvestris | 12 | 0.46 | 1.3 | 43.1 |

Application:

Prev :Exterior Strand Woven Bamboo Decking Carbonized Bamboo Flooring

Next :High Density Carbonized Outdoor Bamboo Decking Flooring with Small Groove