Product Details

Exterior Strand Woven Bamboo Decking Carbonized Bamboo Flooring

Product details:

Item | Exterior Strand Woven Bamboo Decking |

Common size | 1860mmx139mmx18/20/30/38mm |

Color | Coffee color or caramel color |

Surface treatment | bleached, sanded, with UV coating or outdoor oil |

Grain | flat/ big wave/ small ripple/ small groove |

Density | 1200kgs/m3 |

Hardness | 106.8N/mm² |

Expansion Rate After 1 Hour In Boiling Water | 4-5% |

Moisture rate | 7-13% |

Certificate | ISO/SGS/EPH/TUV |

Package | export carton with PVC on pallet |

The difference between wood and bamboo

Although the cellular structure, the Chemical composition and the physical and mechanical properties are similar with the solid wood, but bamboo belongs to grass family since its growth and reproductive pattern is similar with the regular grass and much different from the wood. Bamboo’s rhizome keeps stretching and growing under the ground, then new bamboo shoot will be pregnant and grow up from the rhizome root, from the bamboo shoot to grow up to be a 18 meter long bamboo only need 1 month. When the bamboo is young before the age of 4, the bamboo leaf will absorb CO2(Carbon Dioxide) and N2(Nitrogen) from the air and create nutrition through photosynthesis, then convey the nutrition to the rhizome and promote the rhizome stretch and reproduce new bamboo shoot.but after the bamboo is older than 5 years, the photosynthesis function of the leaf becomes weaker and weaker, and the bamboo stem and leaf need to get nutrition from the rhizome and which will affect the reproduction of the rhizome. When the bamboo is older than 7 years, the bamboo texture will become deteriorating yearly and can’t use for industrial production, then the bamboo will die very soon. So the best harvesting time for industrial usage is when the bamboo is between 4-6 years old.

Thus it can be seen, bamboo grows very quickly and is a sustainable nature resource, if the mature bamboo can be harvest yearly, not only it won’t destroy the environment and the bamboo growth, but it is good for the its reproduction.

Date comparison

Tab.1

Performance | THJ Outdoor bamboo | Nature anticorrosive wood | Man-made anticorrosive wood | Carbonized wood | WPC |

Principal | Through physical process, hot pressing, carbonized | Nature corrosion | Preservative treatment with chemicals | Carbonized in high temperature | Plastic processing technology |

surface | Unique grains of bamboo (brown and dark color) | Keep the original wood grain | Green in color | Dark color-brown | Dull |

Abrasion-resistance corrosion | Excellent | Good | Good | Good | Good |

Environmental preformance | Excellent | Excellent | Bad | Good | Good |

Anti termite | Excellent | Bad | Good | Good | Good |

Stability | Excellent | Good | Easy shaped | Good | Easy shaped in high temperature |

Market price | Middle high | Highest | Low | Middle | Middle Low |

Tab.2

No. | Species | Moisture rate(%) | Density (kg/m3) | Expansion rate of water absorption % | Hardness(Gpa) |

1 | THJ outdoor bamboo | 4.7 | 1.23 | 0.35 | 70.4 |

2 | Teak | 9 | 0.7 | 0.4 | 55.8 |

3 | Merbau | 14 | 0.8 | 0.41 | 61.7 |

4 | Red cedar | 12 | 0.35 | 0.6 | 44.1 |

5 | Jarrah | 17 | 0.57 | 0.6 | 47.1 |

6 | Carbonized pinus sylvestris | 12 | 0.43 | 1 | 44.3 |

7 | Pinus sylvestris | 12 | 0.46 | 1.3 | 43.1 |

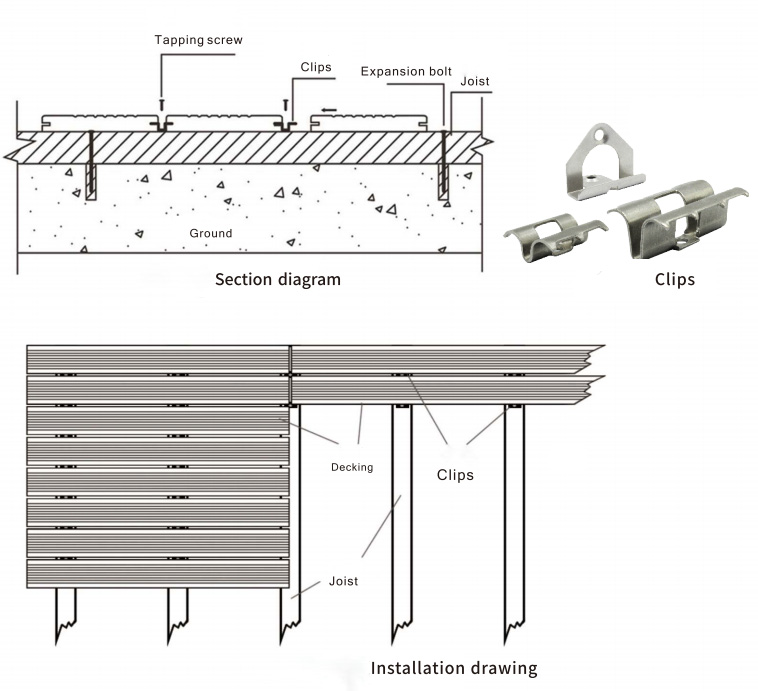

How To Install Taohuajiang Bamboo Decking?

1, Direction of installation

Direction of installation should be kept the same as that of the room length, and the floors be installed one by one from left

or from right with their grooves facing the wall.A fap between floor and wall should be kept 10-15mm and need to put the wood edges.

2, Installation method of flooring

Fix the grooves and tongues of flooring, install the bamboo flooring directly on the base of ground. The end joints of flooring should

be staggered (Generally speaking, on the position of 1/2 or 1/3 staggered). It doesn't need to be nailed or put glues. At the same time,

we should check the straightness and flastness of flooring arrangement when installing. We should also pay attention to the color deviation,

select the similar color floors to be put together. In addition, we can use the color deviation to create shade design, increase the effect of apperance.

3, Keep the flooring in proper tightness when installation

In the areas where there are great differences of moisture in different season, you should keep fitting of boards in proper tightness according

to the weather condition. Floors with lower water rate should be installed loosely when under dry weather conditions; on the contrary, floors

with higher water rate should be installed tightly when under damp conditions. Otherwise, the floors will be curved or swelled or isolated with

the season changing.

4, The last step for installation

· You have to cut some boards when finishing installation. In order to prevent from penetration of water or moisture, edge joints of floors must be painted where it is cut.

· After installation, a few of spring sheets should be placed between the grooves and wall in way of installation without wood strip.

· In some where of the gate and other connecting places, you have to cut some floors so as to leave enough space for welling or shrinkage, then T-molding or reduces can be installed to connect then and cover the space.Meanwhile, there must be 3-5mm space left between the bottom of doors and floor to benefit you open door freely.

· Thickness of baseboards should be less than 14mm. It must cover the swelling gap totally.

Prev :Coffee Color Strand Woven Bamboo Decking Outdoor For Plank Road

Next :Anti-corrosive Outdoor Bamboo Decking Floor , Exterior Bamboo Panels