Product Details

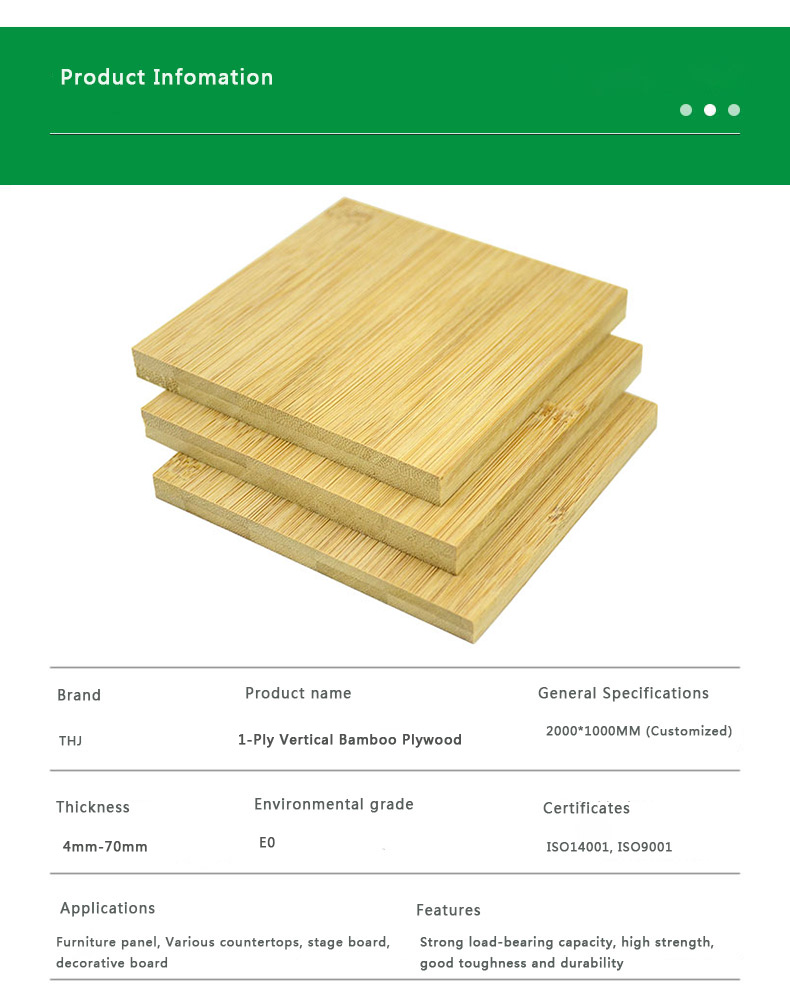

2-Ply Horizontal Solid Bamboo Plywood 20mm Bamboo board for Wall Decoration

Bamboo plywood is made of fine layers of bamboo strips laying in parallel order. The strips are kiln dried, sanded smooth and then laminated edge to edge to create a single-ply panel. These panels are then laminated again to each other to create a multi-ply bamboo plywood with free formaldehyde emission. The multi layers are cross-laminated and heat pressed together to provide stability and to prevent warping. 3-4 times more dimensionally stable than Oak.

PRODUCT DETAILS:

Solid bamboo materials

Common size: 2000mmx800mm; 2000mmx1000mm; 2000mmx1200mm; 2440mmx1220mm; 2440mmx1000mm; 2440mmx800mm; 3000mmx1000mm; 3000mmx1200mm (size can be customized)

Thickness: from 4mm to 70mm

Color: Nature color, carbonized, zebra

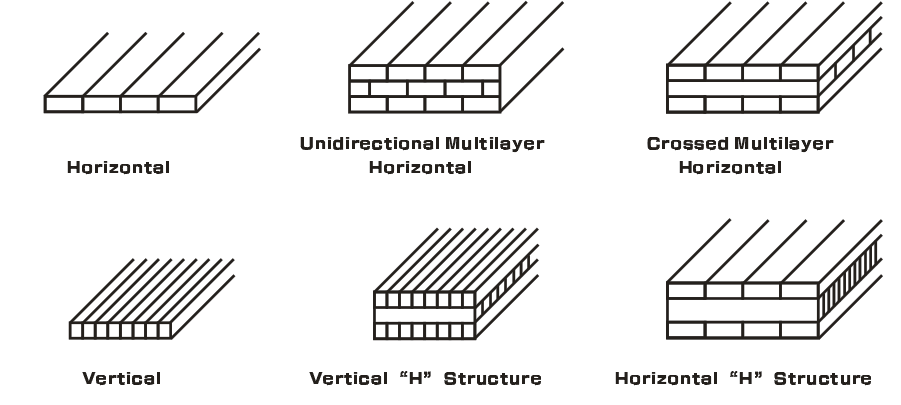

Structure: Horizontal/ Vertical/ H shape/ Crisscross

Density:750kg/M3

Hardness: 32HB

Moisture rate: 8%-12%

Grade: E0

Certificate: ISO/SGS/EPH/TUV

Features: High density/ High intensity/ Elegant/ Termites resistance

Used for : Kitchen cabinet, Kitchen countertop, Furniture, Ceiling, Wall decoration

Package: PVC packed on a pallet

OEM and customization acceptable

Excellent bamboo

Taohuajiang bamboo material is located in Taojiang county, Hunan Province, which is one of China's top ten Bamboo Villages. Based on abundant bamboo resources in Taojiang county, it has many advantages including good toughness and high strength, ensure that the raw material suitable for bamboo processing.

High temperature carbonization

Fresh bamboo contains sugar, bamboo pulp and other organic matter, which will produce insects if long periods of shelving. We use high temperature cooking and other modern technology to remove organic matter and insect eggs in bamboo strips, so that the bamboo is not living in insects.

Three-dimensional drying

Each bamboo strip has been dried and preserved twice, The moisture content is uniform and the physical properties are close to the same. The dislocation type billet makes the stress balance between the layers of the bamboo panel and the structure is stable. After assembling the blanks, placed them for 15 days to balance the moisture, so that the moisture content can be adapted to the climate and environment uses.

Finish planing bamboo strips

In the process of raw material processing, the bamboo strips are finely planed twice after being fully dried to remove the remaining bamboo green and bamboo yellow, and the precision planing error is controlled within 0.05mm to avoid the gap between the bamboo strips and enhance the bonding strength.

Feature bamboo strips

In the process of raw material processing, the finely planed bamboo strips are sorted to secondary sorting, which will be selected the defective bamboo strips , and the qualified bamboo strips for color matching and assembly, it not only retains the natural beauty of bamboo boards but also reduces the range of relative color difference.

Sophisticated technology

Using advanced mechanical equipment for processing, with high precision, which can effectively use materials, and make the appearance and size of the finished product accurate

Imported glue

Using the environmentally friendly tere glue imported from the Netherlands, so that the bamboo gluing process has beautiful and stable appearance, good abrasion resistance and scratch resistance. meanwhile, each batch of products must be tested for abrasion resistance, scratch resistance and environmental protection performance.

Strict Inspection

All products must be inspected and tested by a systematic quality control system. From raw materials to finished products, professional quality inspectors will systematically conduct professional inspections, and the quality of the bamboo panel is stable after testing.

Prev :Eco 1-Ply Horizontal Bamboo Plywood Panels for Kitchen Countertop

Next :1-Ply Natural Vertical Bamboo Plywood Furniture Bamboo Panels