Product Details

Durable Small Ripple Outdoor Bamboo Decking Boards Light Carbonized

The solid bamboo decking boards of THJ anti-corrosive bamboo are made from compressed, heat-treated bamboo chips. THJ Bamboo material is suitable for outdoor applications. Compare with traditional hardwood, THJ bamboo decking boards have many advantages, is one of the plant which grow fastest, which can become useful in 4-6 years and the extending area can reach 3% each year; while it takes 25-50 years for the wood to become useful and its hard to recover after being cut down.

THJ outdoor bamboo decking has good eco-friendly performance, wide usage, elegant look can be created, the grain of bamboo products provided flat, big wave,small wave,double wave and small groove, you can choose the one that suit you. Except for outdoor bamboo decking, bamboo wall cladding, bamboo fencing boards and other indoor bamboo panel which can be used in furniture and handicrafts.

PRODUCT DETAILS:

Common size: 1860mmx139mmx18/20/30/38mm

Tongue&groove

Surface treatment: bleached, sanded, with UV coating or outdoor oil

Color: Coffee color or caramel color

Grain: flat/ big wave/ small ripple/ small groove

Density: 1200kgs/m3

Hardness: 106.8N/mm²

Moisture rate: 7-13%

Expansion Rate After 1 Hour In Boiling Water: 4-5%

Finish: outdoor oiled

Lifetime: 25 years

Certificate: ISO/SGS/EPH/TUV

Features: anti-corrosive, eco-friendly, termites resistance/ fireproof/ anti-friction/ high hardness/ high stability/ high bending strength/ high density.

APPLICATION AREAS: garden, park, swimming pool, commercial buildings and any outdoor environment

PACKAGE: export carton with PVC on pallet

OEM and customization acceptable

Date comparison

Tab.1

Performance | THJ Outdoor bamboo | Nature anticorrosive wood | Man-made anticorrosive wood | Carbonized wood | WPC |

Principal | Through physical process, hot pressing, carbonized | Nature corrosion | Preservative treatment with chemicals | Carbonized in high temperature | Plastic processing technology |

surface | Unique grains of bamboo (brown and dark color) | Keep the original wood grain | Green in color | Dark color-brown | Dull |

Abrasion-resistance corrosion | Excellent | Good | Good | Good | Good |

Environmental preformance | Excellent | Excellent | Bad | Good | Good |

Anti termite | Excellent | Bad | Good | Good | Good |

Stability | Excellent | Good | Easy shaped | Good | Easy shaped in high temperature |

Market price | Middle high | Highest | Low | Middle | Middle Low |

Tab.2

No. | Species | Moisture rate(%) | Density (kg/m3) | Expansion rate of water absorption % | Hardness(Gpa) |

1 | THJ outdoor bamboo | 4.7 | 1.23 | 0.35 | 70.4 |

2 | Teak | 9 | 0.7 | 0.4 | 55.8 |

3 | Merbau | 14 | 0.8 | 0.41 | 61.7 |

4 | Red cedar | 12 | 0.35 | 0.6 | 44.1 |

5 | Jarrah | 17 | 0.57 | 0.6 | 47.1 |

6 | Carbonized pinus sylvestris | 12 | 0.43 | 1 | 44.3 |

7 | Pinus sylvestris | 12 | 0.46 | 1.3 | 43.1 |

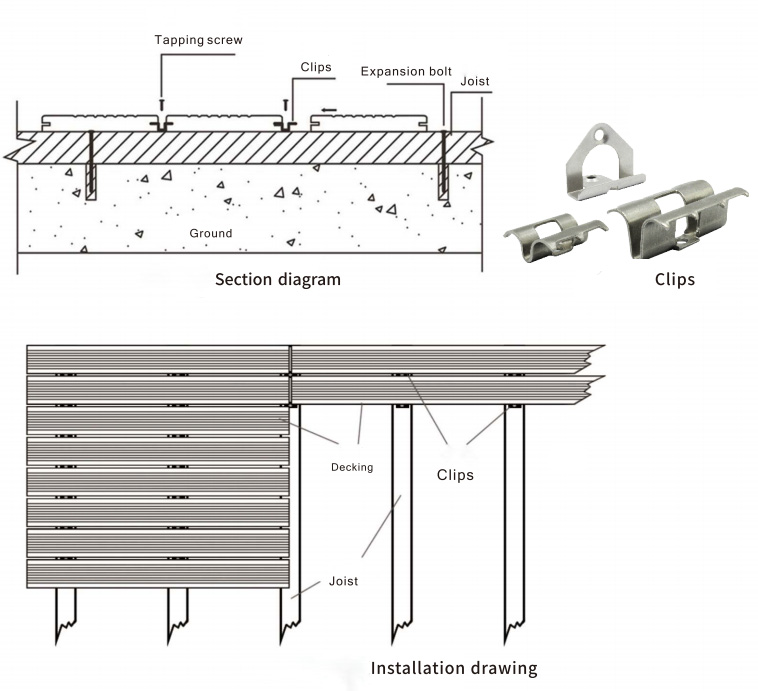

How To Install Taohuajiang Bamboo Flooring?

Compared with other wood:

1. Natural anti-corrosion solid wood (Merbau,Teak, etc )-- Natural and beautiful, but not anti-termite, bad for forests resources,violating the ideas of environmental protection.

2. Chemical anti-corrosion wood ( CCA )-- Containing heavy metals and toxic chemical composition ( Arsenic),polluting environment, prohibited in United States, Japan and EU countries.

3. Chemical anti-corrosion woods ( ACQ ) --Non-toxic processing under chemical methods, bad mucor proof, limited application ( unfavorable to touch soil ).

4. Carbonized wood-- Good Eco-friendly performance, wide usage, but damage to forest resources and limited application ( unfavorable to touch soil ).

5. WPC --A kind of completely industrial products, not natural, easy to be deformed, fragile and broken, hard to be dissolved and not Eco-friendly.

1, Direction of installation

Direction of installation should be kept the same as that of the room length, and the floors be installed one by one from left

or from right with their grooves facing the wall.A fap between floor and wall should be kept 10-15mm and need to put the wood edges.

2, Installation method of flooring

Fix the grooves and tongues of flooring, install the bamboo flooring directly on the base of ground. The end joints of flooring should

be staggered (Generally speaking, on the position of 1/2 or 1/3 staggered). It doesn't need to be nailed or put glues. At the same time,

we should check the straightness and flastness of flooring arrangement when installing. We should also pay attention to the color deviation,

select the similar color floors to be put together. In addition, we can use the color deviation to create shade design, increase the effect of apperance.

3, Keep the flooring in proper tightness when installation

In the areas where there are great differences of moisture in different season, you should keep fitting of boards in proper tightness according

to the weather condition. Floors with lower water rate should be installed loosely when under dry weather conditions; on the contrary, floors

with higher water rate should be installed tightly when under damp conditions. Otherwise, the floors will be curved or swelled or isolated with

the season changing.

4, The last step for installation

· You have to cut some boards when finishing installation. In order to prevent from penetration of water or moisture, edge joints of floors must be painted where it is cut.

· After installation, a few of spring sheets should be placed between the grooves and wall in way of installation without wood strip.

· In some where of the gate and other connecting places, you have to cut some floors so as to leave enough space for welling or shrinkage, then T-molding or reduces can be installed to connect then and cover the space.Meanwhile, there must be 3-5mm space left between the bottom of doors and floor to benefit you open door freely.

· Thickness of baseboards should be less than 14mm. It must cover the swelling gap totally.

Prev :Waterproof Outdoor Strand Woven Bamboo Decking With Hot Pressing

Next :Small Grooved Natural Outdoor Bamboo Decking Board, Solid Bamboo Flooring